Evolabel FlexWipe pallet labeller

Evolabel FlexWipe pallet labeling system turns traditional pallet labelling up-side-down.

Instead of being dangerous, hard to use, large, slow and expensive, the Evolabel FlexWipe system is totally safe, user friendly, compact, fast and cost effective.

Description

Evolabel FlexWipe pallet labeling system turns traditional pallet labelling up-side-down.

Instead of being dangerous, hard to use, large, slow and expensive, the Evolabel FlexWipe system is totally safe, user friendly, compact, fast and cost effective.

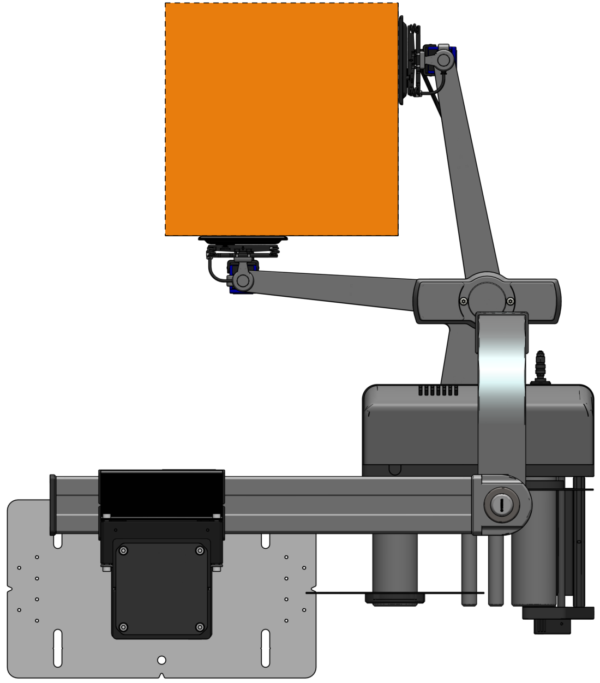

Choose portrait and/or landscape format during label design and let the Multi Side, FlexWipe™ do the rest. No need to change label apply mechanisms as required by most other labelers. In the FlexWipe™, format changes does not slow the labeling speed; the dynamics of the pressurized air –motor controlled, rotational joint, holding the applicator pad keeps the labeling process moving.

The ingenious integration of the code-reading camera combined with the controlled movement of the applicator arm, ensures that 1 or 2D codes are read correctly. This eliminates operational downtime from false negative readings. Red and green lights tell operators the result of the read.

Enhancing safety – The unique Tactile arm eliminates any risk of crushing between the moving applicator arm and the printer or the pallet. If you put your hand in the way, the stepper motor driven arm stops and the system gives an alarm. The Tactile arm together with the Pivotable machine mount, negates the need of expensive guarding. This does not only reduce cost and release floor space, it also gives direct and quick access to the system for the operator. The label roll is replaced within 20 seconds and it takes only a minute to replace the print head or print roller when needed.

The free motion apply (patent pending) allows the same configuration to apply either of the two adjacent sides (side+front or side+back) within 12 seconds. This includes validation of all barcodes on the GS1 SSCC label. The FlexWipe system can label all three sides without having the pallet to stop if check scanning is not required.

The Multiside, FlexWipe™ with optional Motorized Stand XL automatically labels the infamous last, incomplete pallet from a production run. Finally, 100% automation is achieved in pallet labeling! Monitoring the pallets surface with a special sensor, the FlexWipe™ moves down to a suitable labeling surface and only then, applies the label.

Technical info

Suitable printer models: T63 G2

Minimum label size: 80x80 mm

Maximum label size (WxL): 178x240 mm

Label height position (top of label: Standard 770 +/- 400 mm

(Optional 1270 +/- 400 mm)

Label position (symmetric) at min distance (50 mm) between applicator and pallet : 237 mm from pallet corner to near edge of A5 label

Minimum separation between pallets: 750 mm

Label position (assymetric) at smallest possible separation between pallets (450 mm):

Front/Back label: 50 mm from pallet corner to near edge of A5 label

Side label: 343 mm from pallet corner to near edge of A5 label

Distance between applicator and pallet: 215 mm

Air supply: 6 bar, clean and dry

Operating temperature: +5°C to +40°C

Humidity: 20 to 85%, non-condensing

Capacity (2-side labeling): Exceeds 5 pallets/min

Dimensions (WxDxH): 916x610x2047 mm

Options :

Incomplete-pallet detection sensor

Automatic portrait or landscape mode

Barcode validation

Other applicator pad formats available

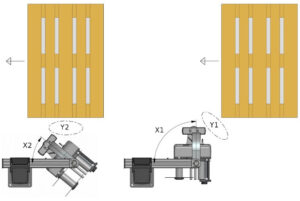

The pivotable machine mount takes away crushing hazards between the moving pallet and the pallet applicator. If a person gets between the moving pallet and the applicator (pos Y1) the applicator will rotate from its operation position X1 towards X2 and further.

This will leave room for the person between the pallet and the system (pos Y2). The system will also detect and alarm so the production line can be stopped. The pivotable machine mount can turn 90 deg counter clock wise and 180 deg clock wise.