Signode Compact 20 and Compact TSI

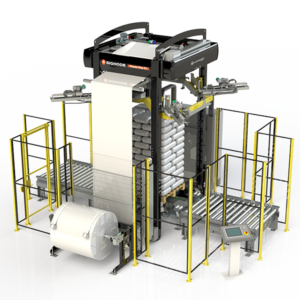

- Compact 20 is a stretch wrapping machine without top sheet dispenser and Compact TSi is a model with integrated top sheet dispenser

- Benefits of ring technology also for low capacity end of line packaging – versatile wrapping features, improved packaging quality

- Integrated Top Sheet Device for packaging quality and space savings

- OctoFACE HMI for visual user experience

- No Touch No Tail seaming device for automatic warehouse compatibility

- Easy and safe maintenance – all preventive maintenance work can be done from the factory floor level

Description

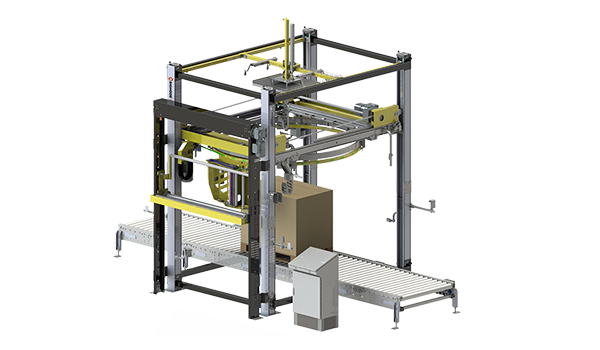

Octopus Compact Series Automatic Rotary Ring Stretch Wrapper

Maximizes Throughput– Wraps up to 40 loads per hour depending on load size and wrap pattern

Robust Construction – Compact, aluminum frame structure provides long-life and minimal maintenance

Simplifies Integration – Requires minimal set-up and less floor space than traditional wrappers

Production Flexibility -Accommodates variable load sizes and multiple wrapping patterns

Signode’s Octopus® Compact Series (Compact 20 / Compact TSi) automatic rotary ring stretch wrapper incorporates the latest technology with the classic octopus ring-type method of wrapping to provide optimal load containment, while optimizing film usage. The Octopus Compact Series features an “S” type film carriage for easy, quick and safe film reel change, less film necking and better pre-stretch performance compared to “W” type film carriages.

Features and Benefits

- Provides unmatched flexibility

Ring design allows for positioning in the vertical direction enabling wrapping to begin and end at any height for unlimited wrap patterns. Ideal for a range of applications including unstable and lightweight products, the Octopus Compact Series has no centrifugal forces simplifying the wrapping of challenging loads. - Unique wrapping approach

The Octopus Compact Series is equipped with No-Touch No-Tail film seaming as a standard feature, eliminating film tails and preventing the seaming device from touching the load itself. - Continuous film force-to-load adjustment

Each wrapping pattern has customized force-to-load settings for individual parts of the load for improved load containment. - Addresses packaging challenges

The TSI model has an integrated top sheet dispenser and protects the load against dust or water ingress. It gives significant space savings on the factory floor and the top film positioning is extremely accurate. It allows a solid top cover that is added during the wrapping cycle without any film seaming on top of the pallet.

Technical info

Octopus_C_Series brochureAdditional standard features

Safety fence with electrical lockout switch and muting

HMI OctoFACE - for improved visual user experience

Options:

Roping device an additional option to form 500 mm wide film a strong 10 mm wide film rope to tie the products to the pallet. The use of a roping increases the overall stability of the pallet transport, reduces the amount of film used for wrapping in the middle and at the top of the pallet and avoids tearing of the film during repeated loading. Highly desirable in the case of heavy cargo pallets.

Tail tucking system: Ropes the film at the end of the cycle and tucks the tail under the layers to eliminate loose tails.