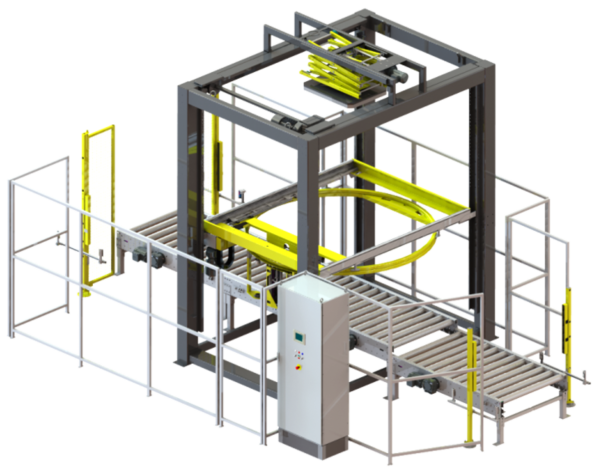

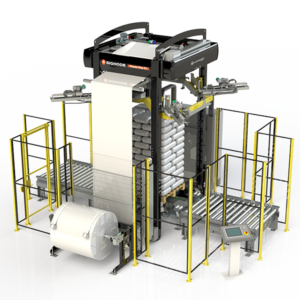

Signode Octopus S Series Automatic Rotary Ring Stretch Wrapper

- Medium and high capacity models, for various load dimensions with different steel frame sizes

- Over size frame e.g. for corrugated & construction industry

- No Touch No Tail film seaming

- Our Octopus S-series stretch wrapping machine is a well proven structure in high capacity production lines, capacity adjusted automatically according line capacity

- Preventive maintenance monitoring

- OctoMAX service concept with on line data monitoring as an option

- Model specified options like double top sheet dispenser

Description

The Signode Octopus S Series automatic rotary ring stretch wrapper is a fully automatic pallet wrapping machine incorporating the latest technology and the famous Octopus ring type method. The Octopus is virtually silent in operation and easily maintained. This versatile machine is modular in design, allowing for numerous innovative options to help solve your specific stretch packaging challenges.

Features and Benefits

- Provides unmatched flexibility

The Octopus S series is ideal for a range of applications including unstable and lightweight products. The machine has no centrifugal forces simplifying the wrapping of challenging loads. - Optimizes film usage

The Easy S film carriage design offers unmatched performance. This unique, easy load film carriage design provides all of the benefits of an “S” wrap while still being very user-friendly. Compared to traditional “W” wrap systems, the positive contact of the “S” wrap pattern improves pre-stretch levels, better handles a variety of films, reduces wear and significantly lowers the overall cost of ownership. Coupled with the innovative ability to vary film force throughout the wrap cycle, the Octopus S series wrappers provide the required load containment force while at the same time optimizing film usage. - Continuous film force-to-load adjustment

Each wrapping pattern has customized force to load settings for individual parts of the load. Based on type of primary packaging, weight of the load, nature of the primary package, and the transport distance of the load, each wrapping pattern will apply top wraps, bottom wraps and film overlaps with individual force to load tensions for improved load containment.

Additional Standard Features

- Safety fence with electrical lockout switch

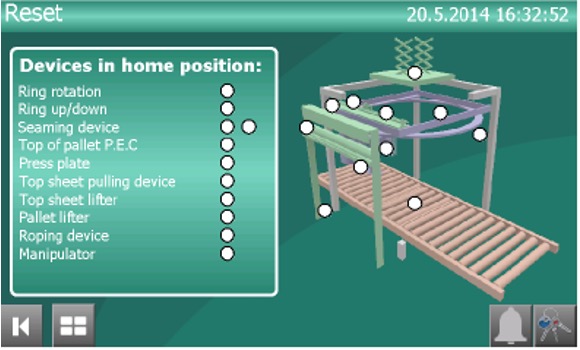

- HMI OctoFACE – for improved visual user experience

- No Touch-No Tail (NT²) seamer offers high-quality, low-maintenance seaming without touching the load

Options

- Load stabilizer: for stabiliziing unstable loads throughout the wrapping cycle

- Integrated top sheet dispenser: Provides automatic weatherproofing without taking up floor space

- Corner post device (CPD): Inserts four solid corner posts at the corners of the load

- Reel change system (RCS): Changes the reels of stretch film without manual intervention, saving time and money

Technical info

Options:

Roping device - Roping is an additional option to form 500 mm wide film a strong 10 mm wide film rope to tie the products to the pallet. The use of a roping increases the overall stability of the pallet transport, reduces the amount of film used for wrapping in the middle and at the top of the pallet and avoids tearing of the film during repeated loading. Highly desirable in the case of heavy cargo pallets.

Flexi roping - an option allows to form a 500 mm wide film into the 10 - 300 mm wide edge reinforced film . This makes possible to increase the transport stability of the load by reinforcing the different parts of the pallet. For products requiring rapid cooling as well as to prevent damage to boxes, labels due to condensation. Recommended for fruit and vegetable bases as well as dairy pallets.

CPD- Octopus corner protectors are placed under the wrapping film on all corners of the pallet. This significantly increases the stability and transportability of the pallets.