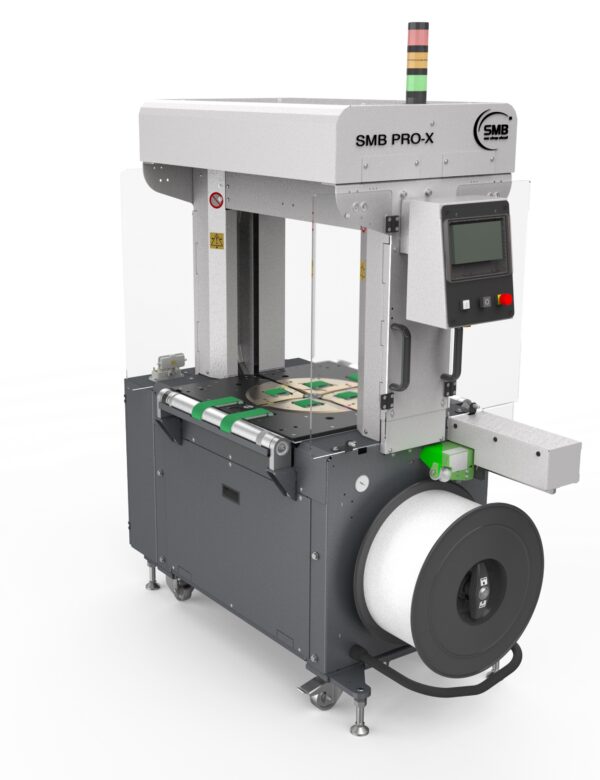

SIGNODE SMB Pro X

The Signode SMB Pro X is a new generation of fully automatic tape machines with a package track. Packs are fed into the machine on a belt conveyor, positioned and taped in the correct position with one or two parallel tapes or 1 x 1 cross tapes. Up to 5000 different product programmes can be stored in the device.

Use of the machine for logistics, mail and printed products.

Description

The Signode SMB Pro X is a new generation of fully automatic strapping machine with a package turner. The packs are fed into the machine on a belt conveyor, positioned and strapped in the correct position with one or two parallel straps or turned and strapped with cross strap. Up to 5000 different product programmes can be stored in the device. The machine communicates with upstream and downstream devices via signal exchange. The speed of the conveyor belts is adjustable, the machine stops when packs not detected.

Steel mono-frame technology is used, giving the machine a long service life with low cost of ownership. We provide a 3 million cycles tape frame warranty. The binding head is easily accessible

ASFL’s anti-failure feature allows you to shorten the time it takes to correct a production problem. Watch the video in the technical info.

The height of the machine’s worktop can be adjusted to a suitable height. The machine uses 50% less energy -0.3kw/h.

Possibility to add a wide range of accessories such as parcel stoppers, upside and side presses, etc.

Technical info

- 5000 bundle recipes

- ASLF 'Anti-Strap-Loss-Function' Constant strap control

- Strap end detection system with automatic discharge of remaining strap

- Automatic strap tensioning, stepless

- Strap coil detection with yellow indicator lamp

- DAT 'Direct-Access-Technology'

- The exclusive eject function avoids strap jam

- Torque controlled strap tension, adjustable

- Upstream and downstream interlocks with complete plug connection

- EPP 'Exact Product Path'

- Conveyor speed steplessly adjustable

- GreenTech energy concept, low power consumption

- Signal light tower: operation and failure

- MFT 'Mono-Frame-Technology'

- Bundle stops, optional

- Bundle press, optional

- Plexiglass side doors, screwed

- Production data analysis via Ethernet/USB

- SMART TOUCH 4.0 – Icon control concept

- Wear-free, energy saving direct-drive-motors

- Wear-free Strap-frame by stainless steel guide

- Many specific options available, easily configurable