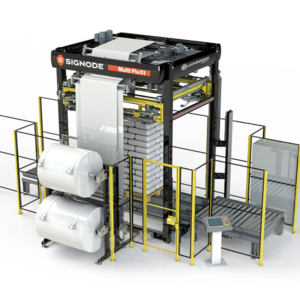

Signode Cobra G rotating arm wrapping machine

The Cobra G is a simple , functional, pre-stretching, rotating arm wrapping machine designed primarily for companies producing a wide range of products of varying weights and dimensions. The Cobra G is suitable for companies that need to pack light, large-heavy, irregularly shaped and unstable products on bases and wheeled trollies that cannot be handled by a turntable machine because the product tray will spread under centrifugal force.

Description

The Cobra G is a simple , functional, pre-stretching, rotating arm wrapping machine designed primarily for companies producing a wide range of products of varying weights and dimensions. The Cobra G is suitable for companies that need to pack light, large-heavy, irregularly shaped and unstable products on bases and wheeled trollies that cannot be handled by a turntable machine because the product tray will spread under centrifugal force.

In the Cobra G, the pallet with the products is stationary and the wrapping head on the console wraps around the product as it rotates. The PPS® pre-stretching system allows film pre-stretching up to 260%. The device has 4 configurable functions : – number of reinforcing straps on the top of the pallet – number of reinforcing straps on the bottom of the pallet – reinforcing straps for heavy products – pallet wrap function. The height of the pallet is determined by means of a photocell attached to the console. A second photo-eye monitors what is happening in the packing zone to ensure the safety of the process. The unit is particularly compact, requiring less than a square metre of space when standing, and is suitable for mounting on a wall or other existing support structure.

We have lifted the Cobra G on top of the existing conveyor line and achieved a stable flow of chassis processing on the production line. To accurately position the chassis in the packing zone, at least a 1.5 m separately controlled conveyor section is required. If you also order additional equipment, it is possible to automate the base coating process for a relatively small investment.

Technical info

Productive up to 35 pallets per hourMaximum product height 2100 mm, 2500 mm, 2900 mm

Filming console diameter 2000 mm, 2400 mm

Maximum base dimensions 1600 mm x 1600 mm x 2900 mm

Rotation speed 12 rpm

Power supply 230 V

Mounting options: On the floor, wall, post

Pre-stretches: 260% standard, 230% and 160% optional