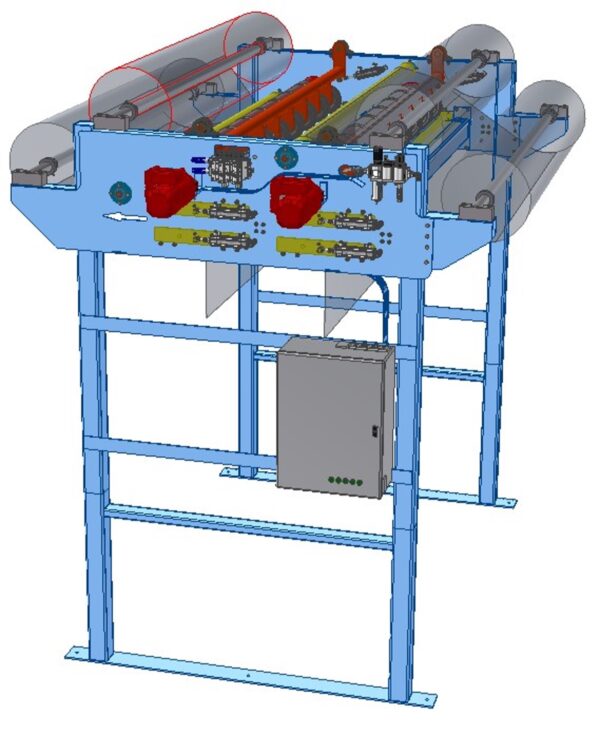

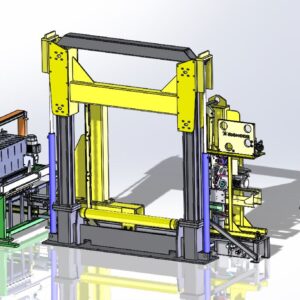

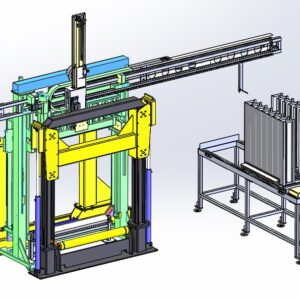

Automatic cover film dispenser D25

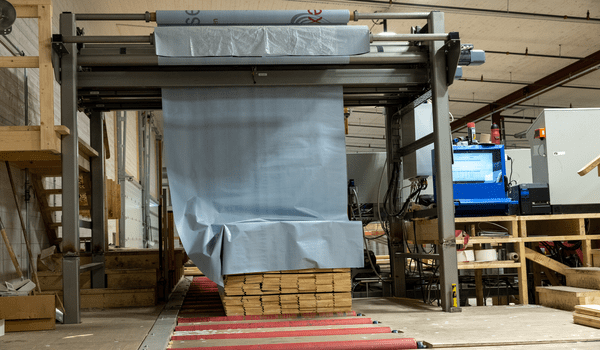

Large lumber packs are covered with plastic films before compression and strapping. Do make this process smooth and easy we are offering Automatic cover film dispenser D25

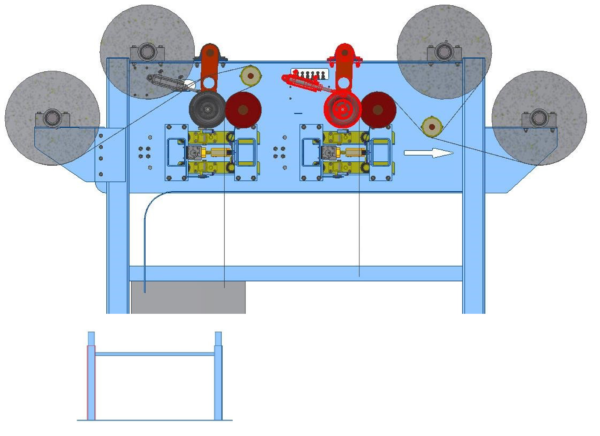

The D25 model has two separate feeders and cutting units. Each unit has access to two separate plastic rolls, for quick reload when one roll is out. In means that there can be four rolls placed on the top of the machine and two of them are loaded to each feeder. The number 25 means maximum plastic roll width 2500mm. Film is folded to the middle. Optional welding unit available to form 5 side hood cover in custom made size.

Description

Large lumber packs are covered with plastic films before compression and strapping. Do make this process smooth and easy we are offering Automatic cover film dispenser D25

- The D25 model has two separate feeders and cutting units. Each unit has access to two separate plastic rolls, for quick reload when one roll is out. In means that there can be four rolls placed on the top of the machine and two of them are loaded to each feeder.

- The number 25 means maximum plastic roll width 2500mm. Normally is the film folded once.

- Machine stand of tubular steel, with separate bottom stands to place on the floor.

- Maximum diameter = Ø500mm. The core tube of the roll shall be Ø76mm inner. A steel tube with adjustable cones will be put trough the roll core.

- Below the plastic rolls there are feeding rollers with friction bands for smooth and secure feeding. Each feeding roll is driven by a flange geared motor SEW-FA47 at 0,75 kw with brake and have an encoder attached for length control

- A beam with counter wheels keeps the plastic towards the feeder roller by two pneumatic cylinders.

- Below the feeder roll are a couple of horizontal pressure beams, one on each side of the roller knife. They will keep the film tight to the cutter beam and are activated by four pneumatic cylinders. Those beams even close the gap, so the knife is guaranteed safety separated from operators’ hands. Separate security sensors check that function before the start of the knife.

- The roller knife runs in a narrow track in the cutter beam, driven by a rodless cylinder, which is mounted on a heavy beam to prevent it from jam damage. The circular knife is elastically fitted to the shuttle to prevent it from any feeding jam.

- There is an option (not included) with a separate measuring wheel to be placed on the conveyer if the speed coordination cannot be done through electronic transfer.

- The electric cabinet is located at either the left or the right side of the stand. The control system contains a Siemens PLC and for the motors SEW converter. The front door holds a touch-control and emergency button. All complete wired and tested before shipping. The machine needs only one phase 230V supply and compressed air. We need to have a complete authentic plastic roll from the customer for testing before chipping, to verify the function. Profibus connection for communication with host computer to get feeding data and the start impulse.

- The machine is prepared for Ethernet connection.

- Pneumatics: Festo.

- The machinery is not depending on the package size. Conveyer speed about 10-25 m/second. Change of feeder can be done from host automation system.

Technical info

Power supply

Main power 240 VAC ± 5 % 1 phase, 50 Hz.

Control circuits 24 VDC.

Compress Air

Required pressure 590 KPa (6,0 kp/cm²)

Allowed Variation Max. ± 49 KPa (± 0,5 kp/cm²)

Quality of air:

In house: Compressed air dried to dew point, approx. + 2° C,

Electronic equipment shall be positioned in an airconditioned place, allowed temperature range15 – 25° C.