Signode Octopus B series

- Well proven ring concept for different load sizes

- A stretch wrapping machine for various capacity needs from low to medium capacity

- Continuous force to load control – wireless technology

- No Touch No Tail film seaming

- Unique solutions for different industrial segments including cold packaging areas

- Preventive maintenance monitoring

- Brick & Pavement -model

- Model for fruit & vegetable packaging

Description

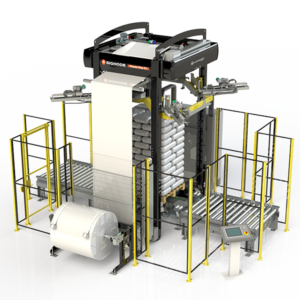

B Series Automatic Ring Stretch Wrapper

The Octopus B Series stretch wrapper is a fully automatic pallet wrapping machine incorporating the latest technology and the famous Octopus ring type method. The film carriage revolves around the load from a rotating ring. The ring is raised and lowered according to the wrapping program. The pallet remains stationary, which makes the wrapping of unstable and lightweight products considerably easier. There are no centrifugal forces to cause stress or strain on the load or on the equipment. Since the sealing mechanism is on the ring, we can start and stop the wrapping cycle anywhere on the load. The Octopus provides optimal load containment while minimizing film usage.

Features and Benefits

- Provides unmatched flexibility

The Octopus B Series stretch wrapper accommodates variable load sizes and features multiple wrapping patterns based on the product to be wrapped. Due to the load being stationary while the ring rotates around it, even very unstable and lightweight products can be wrapped. - Optimizes film usage

The Octopus B wrapper utilizes an “S” style film carriage. Compared to other wrap carriages, its operational efficiency improves pre-stretch levels to minimize film usage, while extending parts life. - Continuous film force-to-load adjustment

Each wrapping pattern has customized force to load settings for individual parts of the load. Based on type of primary packaging, weight of the load, texture of the primary package, and the transport distance of the load, each wrapping pattern will apply top wraps, bottom wraps and film overlaps with individual force-to-load tensions for improved load containment

Additional Standard Features

- Safety fence with electrical lockout switch

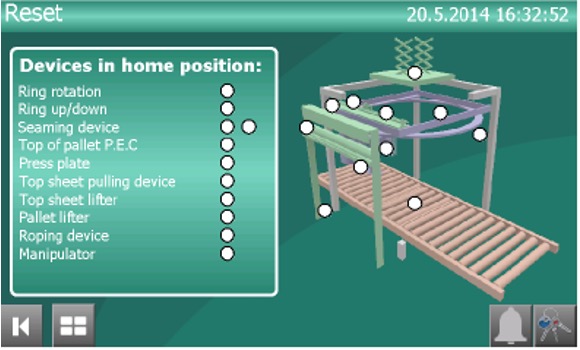

- OctoFACE HMI for a visual user experience

- No Touch-No Tail (NT²) seamer offers high-quality, low-maintenance seaming without touching the load

Options

- Load stabilizer: To stabilize unstable loads throughout the wrapping cycle

- Integrated top sheet dispenser: Provides automatic weatherproofing without taking up floor space

- Corner post device (CPD): Inserts four solid corner posts at the corners of the load

- LogoWRAP: Inserts printed stretch film to a pallet load during the normal wrapping cycle to provide affordable four-sided brand identification

Technical info

Signode Octopus B Seeria tootelehtRotation speed 25-35 rpm

Options:

Flexi Rope - an option allows to form a 500 mm wide film into the 10 - 300 mm wide edge reinforced film . This makes possible to increase the transport stability of the load by reinforcing the different parts of the pallet. For products requiring rapid cooling as well as to prevent damage to boxes, labels due to condensation. Recommended for fruit and vegetable bases as well as dairy pallets.

Roping is an additional option to form 500 mm wide film a strong 10 mm wide film rope to tie the products to the pallet. The use of a roping increases the overall stability of the pallet transport, reduces the amount of film used for wrapping in the middle and at the top of the pallet and avoids tearing of the film during repeated loading. Highly desirable in the case of heavy cargo pallets.