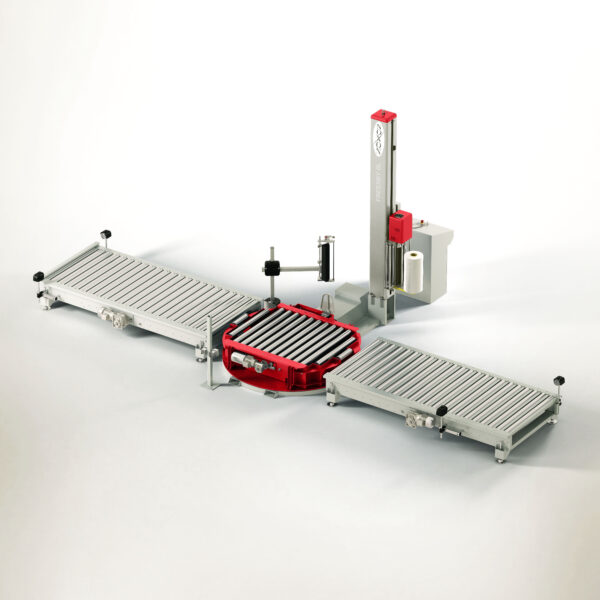

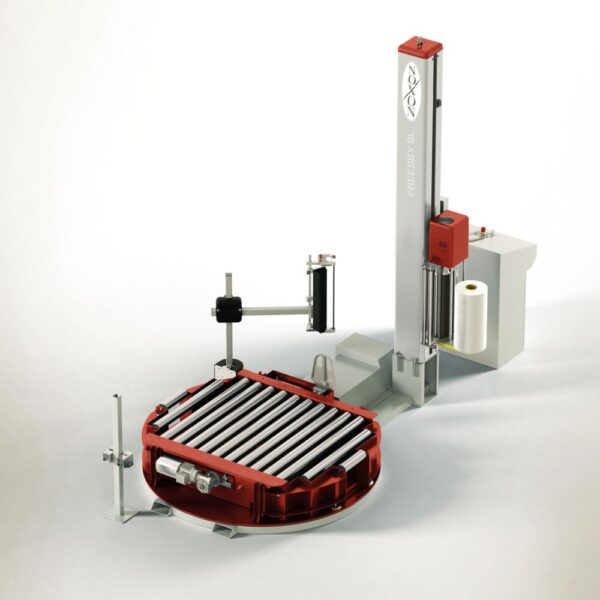

Noxon Freesby SL Fully Automatic wrapping machine

FREESBY SL 212-214 is a high-performance, highly automated wrapping station for an end-of-line packaging.

Rotary table wrapping machine with motorised galvanised rollers for packaging products with vertical shrink film, equipped with gripper, cutting, sealing and tail removal pad device. The machine may be installed in industrial settings at the end of an automatic palletising line.

Description

FREESBY SL 212-214 is a high-performance, highly automated wrapping station for an end-of-line packaging.

Rotary table wrapping machine with motorised galvanised rollers for packaging products with vertical stretch film, equipped with gripper, cutting, sealing and tail removal pad device. The machine may be installed in industrial settings at the end of an automatic palletising line.

212 CARRIAGE

Carriage with double pre-stretch system that can be enabled from the control panel.

The carriage is fitted with fixed 250% pre-stretch (STD).( Opt. Pre-stretch 150%-200%-300% ).

“QLS” quick load system for rapid film insertion.

214 CARRIAGE

Double independent motorisation pre-stretch roller carriage with adjustment from panel of pre-stretch ratio from 150% to 400%. Pressure of application of film on load configurable on the panel and controlled by an electronic device. “QLS” quick load system for rapid film loading.

Technical info

Freesby SL product page| Features | FREESBY SL 212 | FREESBY SL 214 |

| Filming head type | Motorized pre-stretching | 2-engine, variable |

| Film pretension | adjustable from the panel | adjustable from the panel |

| Prestretch | Fixed 250% | variable 150-400% |

| Power supply | VAC 230V 50/60Hz 1Ph+N | |

| Consumption | 4 kW | 4,3 kW |

| Filming head movement speed | 1,5÷5,5 m/min | |

| Turntable speed | 5÷15 rpm | |

| Conveyor speed variable | 8÷11 or 12÷15 m/min | |

| Turntable load capacity | 1500 kg | |

| Front and rear forklift capability | STD |