Signode polypropylene strapping

Polypropylene plastic strapping is designed for light and medium-duty applications, including palletizing, unitizing, bundling, carton closure and reinforcement. It resists splitting and has a smooth, uniform surface so it performs reliably in power strapping machines and hand tools. PP strap has “elastic memory” which absorbs shock and keeps strapping tight during handling and shipping. By choosing Signode Polypropylene strap it is easy to unitize and bundle during your palletising process.

Dylastic strapping has an additive applied to protect its surface from harsh UV light, meaning you can store the product outside without damage and loss of strength. With a broad range of product dimensions available to suit each business needs.

Description

Dylastic® Polypropylene Strapping

Bring your products to its end destination securely with Signode Dylastic Polypropylene Strapping.

Our plastic strapping is manufactured for use with hand tools and high-production power strapping machines. All types have controlled surface properties that minimize tensioning effort, increase tension-transmission around corners and improve operating efficiency.

Dylastic strapping has an additive applied to protect its surface from harsh UV light, meaning you can store the product outside without damage and loss of strength. With a broad range of product dimensions available to suit each business needs.

Features and Benefits

- Suited for packaged goods up to 35Kg in weight

- Designed for packages, loose bundles, newspapers and magazines

- Extra protection for valuable and fragile goods

- Resistant to temperature fluctuations

- An economic solution for logistical and transportation security

Polypropylene (PP) embossed Strapping

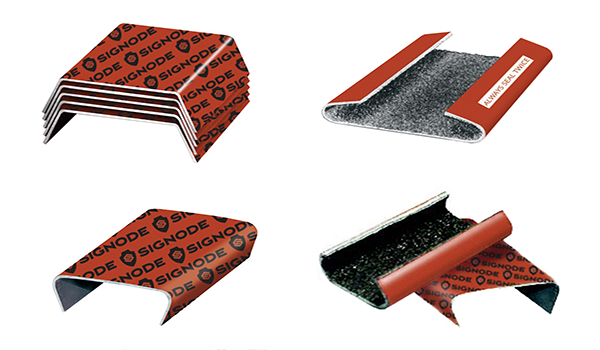

Polypropylene strapping is designed for light and medium-duty applications, including palletizing, unitizing, bundling, carton closure and reinforcement. It resists splitting and has a smooth, uniform surface so it performs reliably in power strapping machines and hand tools. PP strap has “elastic memory” which absorbs shock and keeps strapping tight during handling and shipping. By choosing Signode Polypropylene strap it is easy to unitize and bundle during your palletising process. Suited for all industrial strapping applications, by hand or machine you can be sure Signode polypropylene strapping is efficient to keep items during transit and storage secure and protected. Our plastic polypropylene strapping is available embossed to assist with the prevention of splitting strap and maintaining products securement. Signode PP strapping is available alongside buckles and seals to provide the complete strapping portfolio.

Features and Benefits

- Unparalleled performance

The production of polypropylene offers precision in size, an optimized weight-to-length ratio, and better break strength with tighter dimensional control. This provides fewer misfeeds of straps, leading to increased production efficiency. - Maximum Versatility

It is designed to work smoothly with hand tools and power strapping equipment. It also provides superior performance for light to medium duty bundling and carton closure applications. It has excellent elongation recovery properties, making it ideal for shrinking and compressible loads. - Reduces Cost

It is a more economical packaging solution compared to alternatives. Its lesser weight allows a higher yield which also leads to reduced freight cost.

Technical info

| Signode Dylastic ja SP polypropylen strpping | ||||||

| Application | Width, mm | Tensile | Lenght, | Inside | Standard | |

| strenght | diameter | pallet | ||||

| type | N | mm | mm | |||

| Light product Dylastic | 109W | 5 | 570 | 6000 | 150 | 30 |

| Light product Dylastic | 114W | 5 | 690 | 5300 | 150 | 30 |

| Light product Dylastic | 209 | 6,35 | 640 | 6096 | 102 | 30 |

| Light product Dylastic | 212 | 6,35 | 890 | 4572 | 150 | 30 |

| Light product Dylastic | 610W | 9 | 1210 | 3000 | 200 | 30 |

| Light product Dylastic | 614W | 9 | 1210 | 2800 | 200 | 30 |

| Light product Dylastic | 109WM | 5 | 570 | 7000 | 200 | 24 |

| Light product Dylastic | 114WM | 5 | 800 | 6200 | 200 | 24 |

| Heavy product Dylastic | 714 | 11,1 | 1780 | 3200 | 406 | 12 |

| Heavy product Dylastic | 716 | 11,1 | 2220 | 2438 | 406 | 12 |

| Heavy product Dylastic | 718 | 11,1 | 2670 | 2134 | 406 | 12 |

| Heavy product Dylastic | 935 | 15 | 4500 | 1300 | 406 | 12 |

| LB, SP | SP212 | 6 | 890 | 5105 | 102 | 24 |

| LB, SP | SP654 | 9 | 1335 | 3430 | 200 | 24 |

| SP | SP714 | 11,1 | 1780 | 2515 | 200 | 24 |

| SP | SP716 | 11,1 | 2225 | 2040 | 200 | 24 |

| SP | SP718 | 11,1 | 2670 | 1705 | 200 | 24 |